Equipment overview:This machine is a high-temperature baking equipment, and the working temperature can reach 350 °C. When working, the material first enters the lower hopper of No. 1, and then goes through the vibrating feeder of No. 2 into the screw conveying cylinder of No. 5. The inside of the screw conveying cylinder is heated by No. 7. The fan provides the heat source, and the heat is continuously circulated by the serial number 8 circulating fan to make the inside of the screw conveying cylinder reach 200-350 °C.

Contact Now

Equipment overview:The machine uses the burner for heating, and adopts the drum rotary drying method. It can dry corn flakes, etc. The machine dries evenly, so that the material can achieve the best drying effect.This machine is equipped with advanced temperature control device, which makes the drying temperature set according to different materials accurate and reliable, thus ensuring the excellent quality of drying materials.Equipment structure Device parameters1. Drum drive power: 0.37KW2. Drum size: φ630x2700mm3. Dimensions: 3300×1170×1900mm Precautions1.

Contact Now

Introduction to FLS Snack Products Cooling Conveyor Machine:FLS Snack Products Cooling Conveyor Machine is a supporting equipment for the oven, which is used to cool and transport baked materials. This machine adopts stainless steel mesh belt driven by chain to transport materials.

Contact Now

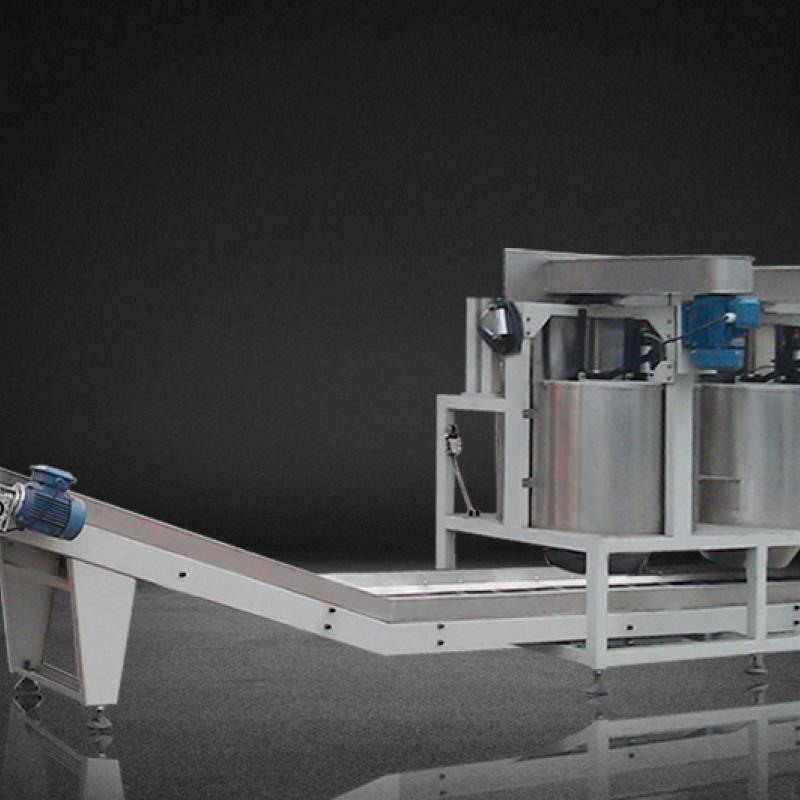

Overview:The equipment is reasonable in design, easy to operate, and low in price. It is also equipped with a chassis for placing the receiving box and discharging conveying.

Contact Now

Equipment introductionThis machine is a special equipment for drying semi-puffed food. It can dry food blanks of various shapes such as potato chips, French fries, spirals, shells and crisp corners. It has a wide range of applications.This machine uses the combustion chamber for heating, and uses the chain to drag the stainless steel mesh belt for transmission. And it is equipped with an advanced frequency conversion speed regulation system, which can set different transmission speeds according to different materials.

Contact Now

OverviewThis complete set of equipment is widely used, and can fry various foods such as potato chips, shrimp sticks, and rice noodles. This complete set of equipment integrates the functions of frying, oil rejection, and lifting. A series of actions are controlled by PLC centralized automatic control, which makes the control accurate and reliable, greatly improves the production efficiency, and saves a lot of human resources.

Contact Now

1. The feeding, rotary cutting and main drive all adopt the frequency conversion speed regulation system, which has strong power and stable operation. 2. The extrusion system is equipped with six sets of temperature control and automatic cooling devices, and the temperature control is accurate and stable. 3. Suspended mold (knife) set seat, which can improve the replacement speed of molds and knives. 4. Double helix forced feeding and photoelectric eye tracking can make the material added evenly and prevent material shortage. 5.

Contact Now

This technique line is one of the newly advanced double-screw extruding techniques of our company. the traditional stir-fry handiwork has low efficient and less usable uncooked substances, and its sanitation and best are hard to govern. the double-screw extruding approach makes up the ones lacknesses. it not best can manner grain materials, like buckwheat, oats, and many others.

Contact Now

This process line uses potato starch, corn starch as main materials to produce a variety of twice extrusion food in different shapes which are popular in the market, such as crispy pea, shell, screw, square tube, round tube, wave, etc. This process line is characterized by unique technics, rational configuration, high automation and stable performance. It can finish steaming, extruding and shaping in one step without a boiler.

Contact Now

Introduction of nutritional rice and instant rice production lineNutritional rice and instant rice production line is a food production equipment developed by Dayi according to the development trend of food in my country.There are two production processes of nutritional type and brewing type. The overall operation is stable, the degree of automation is high, and the operation is simple.

Contact Now

Rice kernal making machine is one of the newly developed double-screw extruding techniques of our corporation. the conventional stir-fry handiwork has low efficient and much less usable uncooked substances, and its sanitation and fine are difficult to govern. the double-screw extruding method makes up the ones lacknesses. it now not handiest can method grain materials, like buckwheat, oats, etc.

Contact Now

Overview:The equipment is reasonable in design, easy to operate, and low in price. It is also equipped with a chassis for placing the receiving box and discharging conveying.

Contact Now

This Puff Snack Making Machine Can Use Corn, Rice, And Other Grain Powder As Raw Materials To Produce Directly Puffed Snacks In Variou Shapes, Such As Chip, Ball, Ring, Stick, Flake, Flower, Etc. After Dried And Flavroed, The Snacks Are Crispy And Tasty Which Are Very Popular In The Market.

Contact Now

Snow flake and bread bran production lineThe snowflake and bread bran production line is exclusively developed and produced by Dayi, which is the first in China and another innovative application of twin-screw extrusion technology. The production process has been fully automated.

Contact Now

The bread crumb production line developed by our company adopts a twin-screw extrusion puffing process, which converts flour or other powdered grain raw materials into crumbs, needle shaped or flake shaped bread crumbs and snowflake flakes. The production process includes feeding, mixing, puffing, cooling, crushing, etc. Compared to traditional baking methods for producing bread bran, the use of puffing technology has advantages such as high yield, high continuous production capacity, energy conservation, and labor saving.

Contact Now

Corn flakes making gadget is one crispy food that is processed with the useful resource of this line using grist as fundamental material. it's far speedy and nourishing food with given form in granule shape, flake shape and animal shape. its extremely good function is containing sufficient compound carbohydrate and meal fibre. breakfast cereal can't handiest supply a boost to lots of microelement which encompass weight loss program and mineral, however moreover be introduced with cocoa powder, sugar powder, honey, and maltose.

Contact Now

EQUIPMENT INTRODUCTION:Using the international advanced twin-screw extrusion technology, combined with our company's rich experience in puffed food technology research for many years, we have developed a puffed food equipment suitable for my country's national conditions. Applicable to a wide range of raw materials,corn, rice, soybean, black rice, mung bean, buckwheat and other whole grains can be used as raw materials.EQUIPMENT ADVANTAGE1.

Contact Now

The product of the utility model is an extrusion type food puffing machine to solve the technical problem that the existing extrusion type food puffing machine has poor puffing effect on food.This extrusion type food puffing machine includes extrusion type food puffing equipment and a decompression module, and the decompression module is arranged at a matching position at the puffing outlet of the extrusion type food puffing equipment, so that the air pressure at the puffing outlet is lower than the environment air pressure.First of all, the decompression module includes ventilation equipment,

Contact Now

This process line is one of the newly developed double-screw extruding techniques of our company. The traditional stir-fry handiwork has low efficient and less usable raw materials, and its sanitation and quality are difficult to control. The double-screw extruding technique makes up those lacknesses. It not only can process grain materials, like buckwheat, oats, etc.

Contact Now

This puff snack making device can use corn, rice, and distinctive grain powder as uncooked materials to deliver right away puffed snacks in variou shapes, collectively with chip, ball, ring, stick, flake, flower, and lots of others. after dried and flavroed, the snacks are crispy and attractive which might be very well-known within the marketplace.

Contact Now

Breadcrumb is mainly used for fried beefsteak and chicken as frying dressing. this line is especially designed and developed to perform from the fabric to very last shaping routinely with less manpower, with out waste,lower production price, and higher manufacturing efficiency.

Contact Now

Bugles making machine makes use of corn powder, corn starch, and rice powder as most important material that are extruded, punched into triangle, round, square shapes, after which baked and flavored. such snacks with crispy flavor, rich nutrition and digestible structure are very popular with many people all over the global.

Contact Now

Tortilla chip process line uses corn powder, corn starch, and rice powder as main material which are extruded, punched into triangle, round, square shapes, and then baked and flavored. Such snacks with crispy taste, rich nutrition and digestible structure are very popular with many people all over the world.

Contact Now

Equipment introductionThis complete set of equipment is widely used, and can fry various foods such as potato chips, shrimp sticks, and rice noodles. This complete set of equipment integrates the functions of frying, conveying, oil filtering and seasoning, and the control is accurate and reliable. The equipment is frying while conveying, with strong continuous production without interruption, which greatly improves production efficiency and saves a lot of human resources. Frying oil turnover rate is high. The pot body and the conveying can be separated freely, which is

Contact Now